In today’s fast-paced world, the demand for efficient and streamlined supply chain management has never been greater. Two key terms that often come up in discussions about optimizing the movement of goods are “warehouse automation” and “Logistics Automation.” While these terms may sound similar, they refer to distinct aspects of the supply chain. Understanding the differences between warehouse automation and logistics automation is essential for businesses looking to improve their operations and stay competitive in the modern marketplace.

Table of Contents

Warehouse Automation: Streamlining Operations in the Four Walls

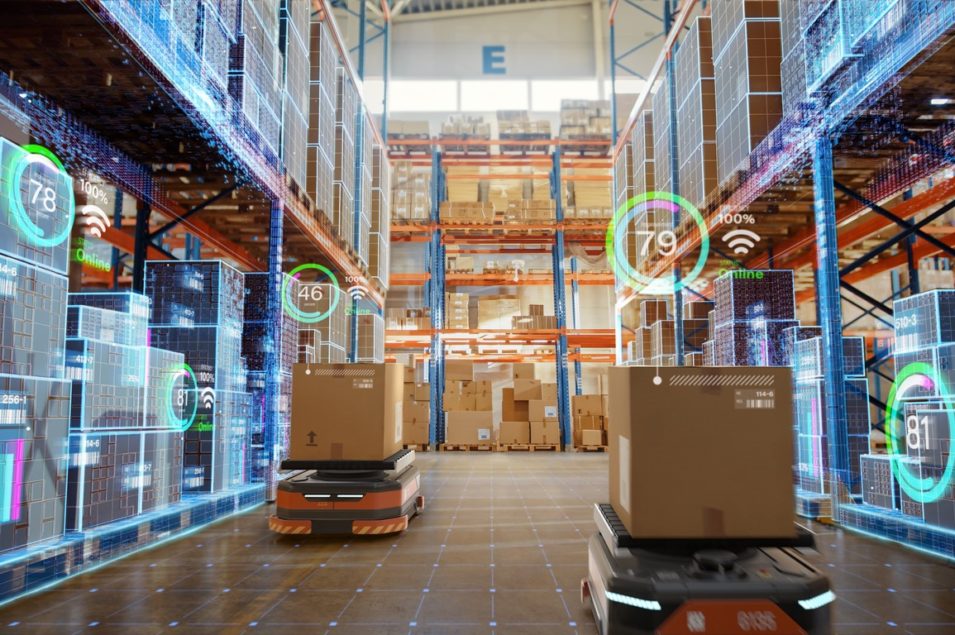

Warehouse automation focuses on the automation of processes within the physical confines of a warehouse or distribution center. This includes everything from receiving goods, storing them, and then picking, packing, and shipping them to customers. Warehouse automation solutions are designed to optimize and simplify these internal operations, leading to increased efficiency, accuracy, and cost savings.

Key Components of Warehouse Automation:

- Automated Storage and Retrieval Systems (AS/RS): AS/RS systems use robots and conveyors to automatically store and retrieve items, reducing the need for human intervention and minimizing the risk of errors.

- Pick and Pack Systems: Automation is applied to the process of selecting products from inventory and packing them for shipment, leading to faster and more accurate order fulfillment.

- Conveyor Systems: Conveyor belts are used to transport goods efficiently within the warehouse, reducing manual handling and speeding up processes.

- Robotic Systems: Autonomous robots, guided by AI and sensors, can navigate the warehouse to perform tasks such as inventory counting, restocking, and order picking.

- Automated Guided Vehicles (AGVs): AGVs are mobile robots used for material transport, helping to move products between different parts of the warehouse.

- Barcode and RFID Systems: These technologies are crucial for tracking and managing inventory, ensuring accurate stock levels, and improving order accuracy.

Advantages of Warehouse Automation:

- Improved Efficiency: Warehouse automation reduces the need for manual labor, which can be slow and error-prone. This results in faster order processing and reduced labor costs.

- Enhanced Accuracy: Automated systems are highly precise, minimizing the risk of errors in order picking, packing, and inventory management.

- Optimized Space Utilization: AS/RS systems, for instance, can maximize vertical space in the warehouse, allowing for more products to be stored in a smaller footprint.

- Reduced Operational Costs: Automation can lead to savings on labor, space, and energy costs, contributing to a more cost-effective warehouse operation.

- Scalability: Automation systems can be scaled up or down to match the needs of the business, making it easier to adapt to changing market conditions.

While warehouse automation primarily focuses on processes within the physical warehouse, logistics automation takes a broader view, encompassing the entire supply chain from end to end.

Logistics Automation: Coordinating the Supply Chain

Logistics automation, on the other hand, encompasses a wider range of processes, including those that occur outside the walls of a warehouse or distribution center. It is about orchestrating and optimizing the flow of goods from the manufacturer to the end customer, involving various modes of transportation, inventory management, demand forecasting, and more.

Key Components of Logistics Automation:

- Transportation Management Systems (TMS): TMS software helps manage the movement of goods from point A to point B, optimizing routes, reducing transportation costs, and ensuring timely deliveries.

- Inventory Management Systems: These systems monitor and control inventory levels, ensuring that products are available when needed without excessive stockpiling.

- Demand Forecasting: Accurate demand forecasting helps businesses anticipate customer needs and adjust their supply chain accordingly, reducing the risk of overstock or stockouts.

- Order Management Systems (OMS): OMS solutions track and manage orders from the moment they are placed until they are delivered, ensuring seamless order processing and customer satisfaction.

- Warehouse Management Systems (WMS): WMS software bridges the gap between warehouse operations and logistics, facilitating real-time coordination between the two.

- Track and Trace Technologies: Technologies like GPS and RFID allow for real-time tracking of shipments, improving visibility and transparency throughout the supply chain.

Advantages of Logistics Automation:

- Enhanced Visibility: Logistics automation provides real-time visibility into the entire supply chain, allowing businesses to make informed decisions and respond to issues promptly.

- Reduced Transportation Costs: Optimized routes and efficient transportation management result in lower shipping costs and faster deliveries.

- Inventory Optimization: Automated inventory management ensures that products are available when needed, reducing carrying costs and preventing stockouts.

- Improved Customer Satisfaction: seamless order processing, accurate delivery estimates, and proactive issue resolution all contribute to higher customer satisfaction levels.

- Adaptability: Logistics automation allows businesses to adapt to changing market conditions and customer preferences more effectively.

Overlap and Synergy

While warehouse automation and logistics automation have distinct focuses, they are not mutually exclusive. In fact, they often complement each other, creating a synergy that results in a highly efficient and responsive supply chain.

1. Warehouse Management System (WMS): WMS software is a prime example of a technology that bridges the gap between warehouse automation and logistics automation. It allows for real-time communication and coordination between the warehouse and the broader supply chain. For instance, if a logistics hiccup causes a delay in the arrival of goods, the WMS can adjust warehouse priorities to ensure that critical orders are still processed on time.

2. Robotics and AGVs: Autonomous robots and AGVs used in warehouse automation can seamlessly integrate into logistics automation by handling the movement of goods within the warehouse and helping with transportation to and from the warehouse.

3. Data Integration: Both warehouse and logistics automation generate a wealth of data that can be analyzed and used to improve operations. Data analytics and reporting tools can provide insights into performance, helping businesses make informed decisions and optimize their supply chain further.

Challenges in Implementing Automation

Implementing warehouse and logistics automation is not without its challenges. While the benefits are substantial, it’s essential to be aware of potential roadblocks and address them effectively.

1. High Initial Costs: Automation systems can be expensive to implement, requiring a significant upfront investment in technology and infrastructure. However, these costs should be weighed against the long-term benefits and cost savings.

2. Integration Complexity: Integrating different automation systems and ensuring they work seamlessly together can be a complex task. It often requires expertise in both automation technologies and supply chain management.

3. Workforce Transition: Transitioning from a manual labor-intensive operation to automation may require retraining or reassigning existing employees, and it can be met with resistance from the workforce.

4. Scalability: Ensuring that automation systems can scale to accommodate growth or seasonal fluctuations in demand is a critical consideration. Scalability requires careful planning to avoid bottlenecks or underutilization of resources.

5. Technological Obsolescence: As technology evolves rapidly, the risk of automation systems becoming outdated is a concern. It’s essential to choose systems that can adapt and evolve with the business.

Warehouse Automation vs. Logistics Automation: Making the Choice

When deciding between warehouse automation and logistics automation, it’s crucial to consider the specific needs and challenges of your business. In some cases, it may be beneficial to prioritize one type of automation over the other, but often a combination of both will yield the best results.

When to Prioritize Warehouse Automation:

- If your business primarily deals with the efficient storage, picking, packing, and shipping of products from a centralized location,

- Order accuracy, speed, and labor cost reduction are top priorities.

- If you have a high volume of repetitive tasks that can be automated within the four walls of your warehouse,

To prioritize logistics automation:

- If your supply chain involves multiple locations, transportation, and complex coordination between them.

- Demand forecasting, route optimization, and transportation cost reduction are critical factors.

- If you need end-to-end visibility and control over your entire supply chain, from manufacturing to the customer’s doorstep.

The Ideal Scenario: A Holistic Approach

In many cases, the ideal scenario involves adopting both warehouse and logistics automation in a coordinated and holistic manner. By doing so, businesses can achieve seamless end-to-end automation that optimizes the entire supply chain, from raw materials to final delivery. This approach can enhance operational efficiency, reduce costs, improve customer satisfaction, and create a more agile and adaptable business.

For example, a clothing retailer with both physical stores and an online presence may benefit from warehouse automation to efficiently manage inventory and fulfill online orders, while also leveraging logistics automation to optimize transportation routes and coordinate the delivery of products to various locations.

Conclusion

In conclusion, while the terms “warehouse automation” and “logistics automation” may sound similar, they represent different facets of supply chain management. Warehouse automation focuses on streamlining processes within a physical warehouse, improving internal operations, and reducing manual labor. Logistics automation, on the other hand, takes a broader view of the entire supply chain, encompassing transportation, inventory management, demand forecasting, and more.

Both forms of automation offer significant advantages, and they are not mutually exclusive. In fact, they often work together to create a more efficient and responsive supply chain. When choosing between warehouse and logistics automation, businesses should consider their specific needs, challenges, and long-term goals, but in many cases, a combination of both is the key to success in today’s competitive marketplace. With careful planning, implementation, and ongoing optimization, businesses can harness the power of automation to stay ahead of the curve and meet the evolving demands of their customers.